The ABCs of LVT

Understanding Luxury Vinyl Tile

Over the years, Luxury Vinyl Tile (LVT) has evolved into one of the most innovative and cost-effective flooring solutions on the market. Also known as luxury vinyl plank and luxury vinyl flooring, it’s seemingly everywhere. LVT meets the practical needs of a wide variety of residential and commercial projects—and looks good doing it. To understand how TileBar LVT is constructed, as well as the benefits and possibilities it has to offer, you’ll want to familiarize yourself with some technical (and not-so-technical) terms.

This glossary is here to help.

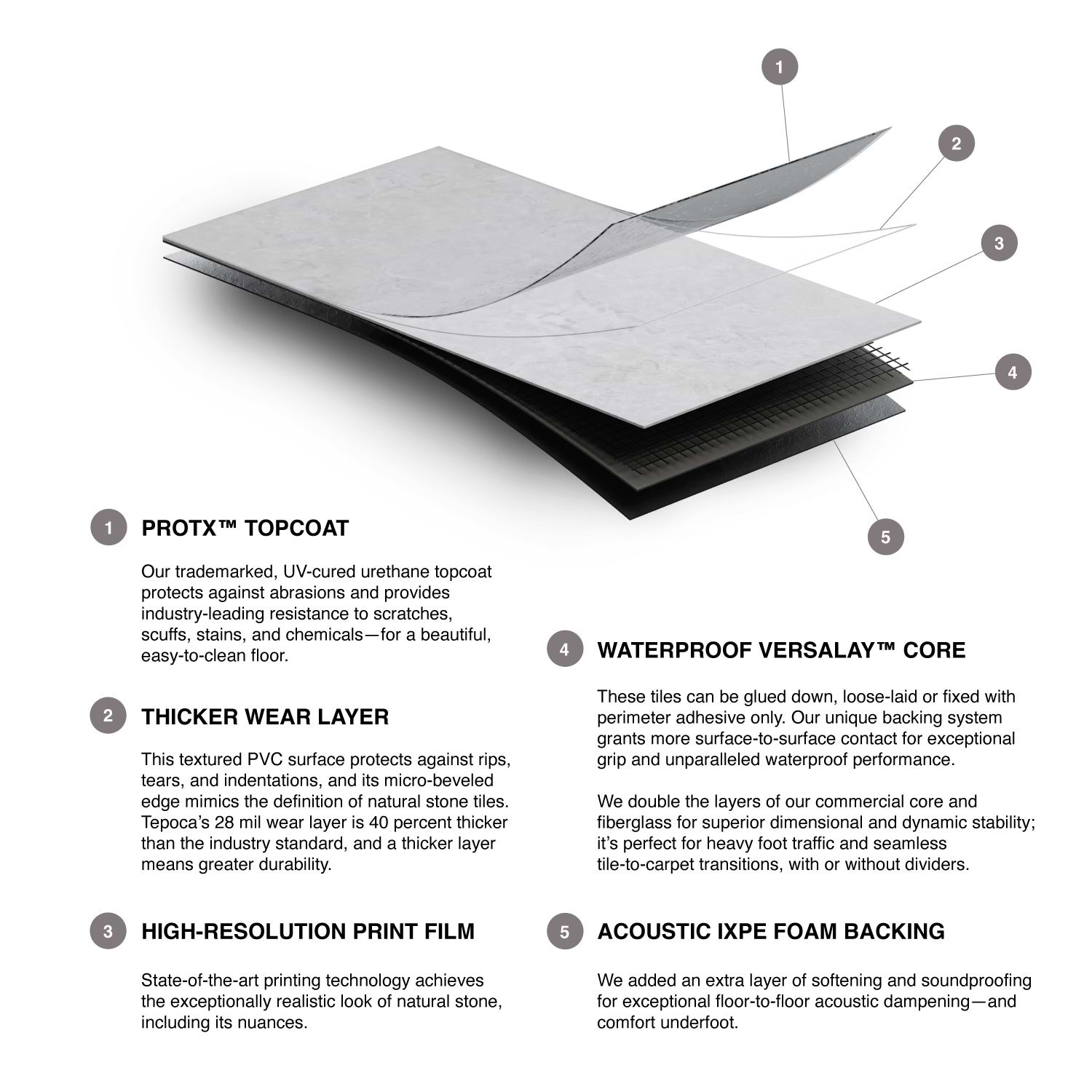

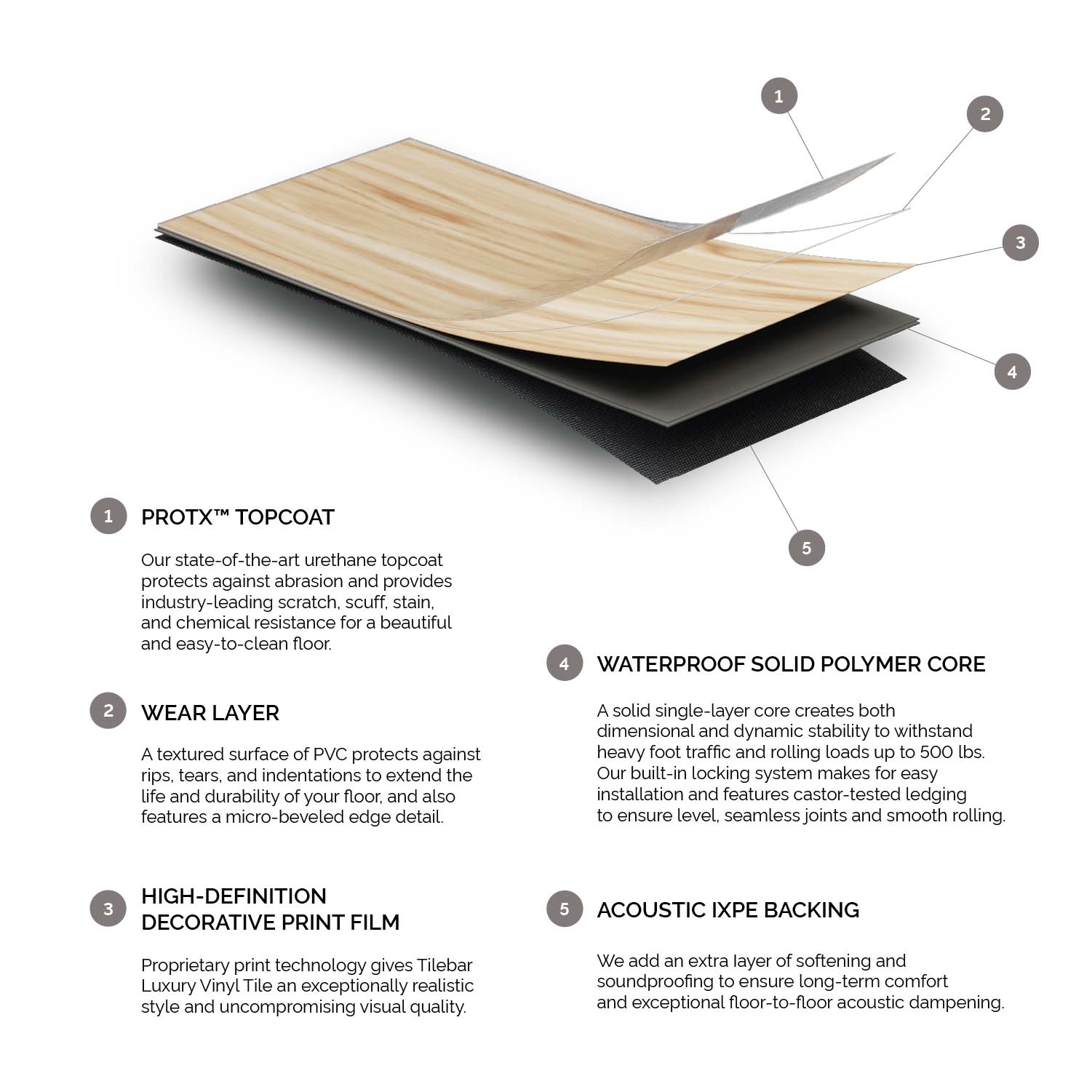

ACOUSTIC IXPE FOAM BACKING

The bottommost layer of each plank of TileBar Rigid Core click and VersaLay™ LVT absorbs sound waves, helping to reduce noise. IXPE (which stands for irradiated cross-linked polyethylene foam) also protects your flooring from mold, bacteria, mildew, and rot. Additionally, the softness of this base layer makes our LVT noticeably comfortable to stand and walk on.

HIGH-RESOLUTION PRINT FILM LAYER

The middle layer of each plank of TileBar LVT features a high-definition print of a wood grain or stone surface. The innovative printing technology used achieves a realistic look with all the nuances and variations of the real material.

LUXURY VINYL FLOORING, LUXURY VINYL TILE, AND LUXURY VINYL PLANK

Luxury Vinyl Flooring (LVF) is a broad term that encompasses all multi-layered luxury vinyl products. The key difference between Luxury Vinyl Tile (LVT) and Luxury Vinyl Plank (LVP) is their shape. LVT refers to products that have square or rectangular dimensions, like a tile. LVP refers to products that are long and narrow, like genuine wood plank flooring.

MICRO-BEVELED EDGES

Planks that have a slight slope to their edges are referred to as micro-beveled. When these edges meet between two planks, they form a shallow ‘V’-shape. This is a stylistic finishing touch that helps accentuate the shape of the plank. It’s characteristic of modern natural wood flooring.

PROTX™ TOPCOAT

This is the uppermost layer of a TileBar LVT plank. Our trademarked, UV-cured urethane topcoat provides industry-leading resistance to scratches, scuffs, stains, and chemicals. Urethane is a synthetic material that falls between plastic and rubber. It becomes exceptionally hard when it undergoes the UV-curing process. This topcoat keeps your floors looking beautiful, and makes them easy to clean, too.

RIGID CORE, WOOD PLASTIC CORE, STONE PLASTIC CORE, AND MgO BOARD

Rigid Core is a category of highly durable and dimensionally stable luxury vinyl flooring that includes Wood Plastic Composite (WPC), Stone Plastic Composite (SPC), and Magnesium Oxide Board (MgO) flooring products. WPC products have a core partially composed of wood fibers, making them extra-soft underfoot and excellent at absorbing sound. The core of SPC products contains limestone, making them highly durable, and preferred by many manufacturers. MgO products have a mineral core, making them fireproof and environmentally friendly.

ROLLING LOADS

Referring to weight on wheels, a rolling load can be a person scooting around in an office chair, or a dolly stacked with boxes. TileBar’s Rigid Core Click LVT collections are tested to withstand rolling loads up to 500 pounds, as well as heavy foot traffic. TileBar’s glue-down LVT can withstand rolling loads up to 2,000 pounds.

SLIP-RESISTANCE

All flooring products are tested for their resistance to slippage. Experts have developed testing standards to evaluate slip resistance in both wet and dry situations. The embossed texture of the wear layer provides exceptional slip resistance, an important feature in both residential and commercial settings.

SUBFLOOR

Subfloors are the surfaces beneath the floors we walk on every day. They can be made of wood, concrete, stone, or metal. Subfloors must be prepped to successfully install LVT (or any other type of flooring). This means they should be clean and dry. The subfloor surface should be as flat as possible, without any protruding nails or screws. Uneven surfaces should be sanded and/or leveled. Gaps can be filled with caulk or cement, depending on the subfloor material. Always follow all installation instructions to ensure that your flooring is installed correctly.

VERSALAY™

TileBar’s VersaLay™ is an innovation in the flooring industry that allows you to choose from three installation methods, according to the needs of your project. These are loose-lay, perimeter adhesive, and glue-down. LVT products with VersaLay™ also include an additional layer of fiberglass for dimensional stability.

- LOOSE-LAY.The simplest installation option, loose-lay doesn’t rely on adhesives to hold planks in place. Flooring goes down quickly, relies on friction to remain in place over time, and can be installed over existing flooring. Loose-lay is best used in smaller spaces with light traffic; if necessary, planks can be replaced with ease. It’s as simple as it sounds.

- PERIMETER & GRID SYSTEM ADHESIVE.With this method, glue is applied around the perimeter of a space, as well as to 4-inch bands every 8 feet. It’s fairly forgiving of errors in its installation, and at the same time provides more stability than loose-lay. This installation method is best for mid-sized spaces with moderate traffic.

- GLUE-DOWN.It’s just what it sounds like. This permanent installation method requires the use of adhesive applied throughout the subfloor. It’s best for areas that withstand heavier traffic or rolling loads. This might include offices, schools, hospitals, hotels, or larger residential spaces.

WATERPROOF SPC CORE

This is the solid, single-layer core in the middle of an LVT plank. It creates dimensional stability, and because this layer is waterproof, it resists spills and keeps them from seeping into the subfloor. It also keeps planks from expanding, contracting, peeling, or warping, preventing future problems, and saving time and money.

WEAR LAYER

This is the second layer from the surface of an LVT plank. Composed of PVC, the wear layer protects against rips and tears, and provides overall durability. Much of TileBar’s LVT features a 28 mil-thick wear layer, which is 40 percent thicker than the industry standard. In addition to providing resilience, this layer also has aesthetic qualities. It can be embossed with the texture of the material it’s simulating, such as wood or stone. It’s micro-beveled too, giving it a realistic finishing touch.

Related Articles

Choosing the Right Grout

Find Your Perfect Grout Match! Color, Texture & Choosing for Your Tile.

OTHER PRODUCTS USED: